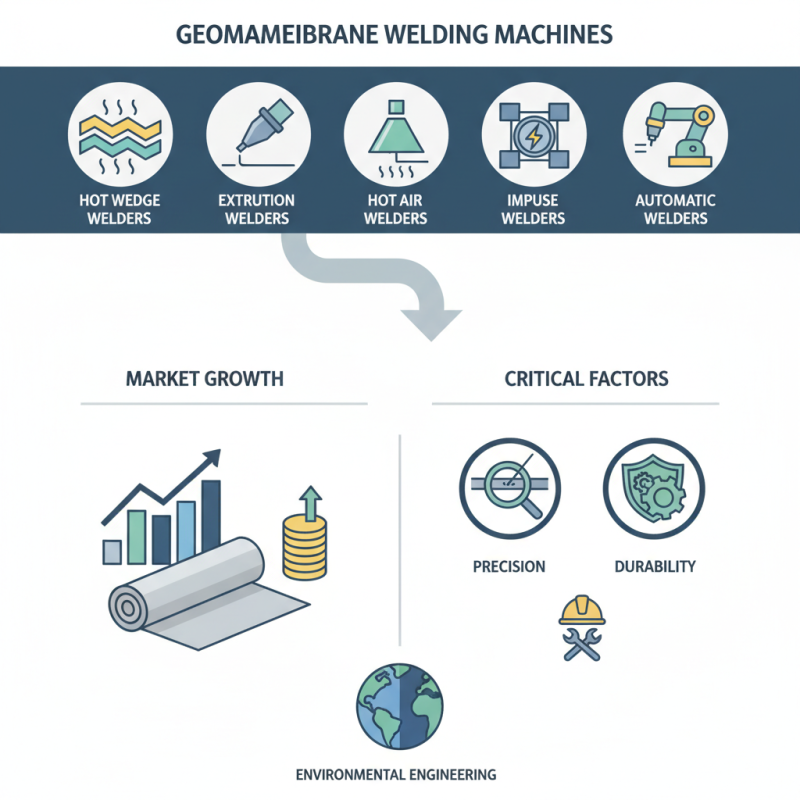

Best 5 Geomembrane Welding Machines You Should Know?

In the construction and environmental engineering sectors, the demand for efficient geomembrane welding machines is growing steadily. According to a report from the Geosynthetic Institute, the geomembrane market is expected to reach $3 billion by 2025. This surge highlights the crucial role of geomembrane welding machines in ensuring proper installation and longevity of geosynthetic liners.

Industry experts emphasize the importance of high-quality welding. Dr. Jane Smith, a renowned expert in geosynthetic materials, states, “Choosing the right geomembrane welding machine can make or break a project.” Her insight underscores the need for reliable equipment. Welding machines must deliver precision and durability to meet performance standards.

However, not all machines are created equal. Some may lack features necessary for specific applications. It's vital to evaluate machines thoroughly before making a purchase. Without careful consideration, projects may face delays or increased costs. As the industry evolves, staying informed about the best geomembrane welding machines is essential for success.

Overview of Geomembrane Welding Machines

Geomembrane welding machines play a vital role in the construction and environmental protection sectors. These machines are essential for ensuring impermeable barriers in landfills, ponds, and canals. Properly welded geomembranes prevent leaks and protect groundwater from contamination. According to industry reports, the demand for geomembrane welding equipment is expected to grow annually by about 5.6% through 2026. This growth is driven by increased environmental regulations and the need for effective waste management solutions.

Tip: When selecting a geomembrane welding machine, consider its temperature control capability. Machines with precise temperature settings lead to stronger welds and better durability. It’s crucial to understand the material types you’ll be working with. For instance, high-density polyethylene (HDPE) requires different welding techniques than polyvinyl chloride (PVC).

Another important factor is the machine’s mobility. Some projects require welding in remote areas. A lightweight, portable option can save time and reduce labor costs. However, consider that portability may lead to compromises in power and efficiency. It’s essential to balance functionality with convenience. Always seek trained personnel to operate these machines to avoid costly mistakes during the weld process.

Key Features to Look for in Geomembrane Welders

When searching for the best geomembrane welding machines, certain features are essential. First, consider the machine's temperature control. This ensures consistent heat distribution for strong seams. A reliable temperature range is crucial for various materials. A machine that can quickly adjust its heat settings saves time and improves efficiency in the field.

Next, look into the pressure settings offered. Proper pressure is vital for achieving tight welds. Machines that allow for adjustable pressure create stronger joints. Also, portability plays a significant role. Lightweight and compact designs enable easy transport and setup. You want a machine that you can easily move across job sites without hassle.

Lastly, consider the ease of use. Machines with intuitive controls help reduce the learning curve for operators. However, some machines may be complex and overwhelming. It's essential to find a balance between advanced features and usability. Test the machine if possible. Spend time understanding its capabilities. This knowledge will improve your overall performance and lead to better results.

Top 5 Geomembrane Welding Machines on the Market

When it comes to geomembrane welding machines, several options stand out in the market. The right choice depends on specific needs. Some machines excel in speed, while others focus on precision. Understanding these differences can save time and resources.

Features often include automatic adjustments and temperature controls. These functionalities enhance the welding process. However, some users may find the setup complex. Familiarity with the machine is crucial for optimal results. Beginners should invest time in training to avoid common mistakes.

Portable Machine Portability is another key factor to consider. Some welding machines are lightweight and easy to carry. Others are bulky but offer greater stability. Weight affects site mobility and can lead to decreased efficiency. Users need to balance these aspects for their specific projects. The ideal machine should cater to both convenience and functionality.

Comparison of Performance and Technology in Welding Machines

When selecting a geomembrane welding machine, performance and technology play crucial roles. Efficiency is key. High-speed welding capabilities often lead to better productivity. However, machines that promise speed can sometimes compromise welding quality. This is a common concern among users, who report variable results based on material types and environmental conditions.

Different welding technologies affect the end product. Hot air welding is popular but requires precision. The operator’s skill is paramount here, as misalignment can ruin a seam. On the other hand, wedge welding offers greater consistency. The heating element uniformly melts the geomembrane edges, which can enhance durability.

Still, it can be less adaptable in field conditions.

Power supply is another factor impacting performance. Machines with stronger motors typically handle thicker materials effectively. However, this doesn’t mean they’re suitable for all jobs. Portability may suffer, making transportation difficult. Balancing power with function can be tricky. Users often find themselves pondering which attributes meet their specific needs best. It's essential to weigh these aspects carefully before making a decision.

Maintenance Tips for Geomembrane Welding Equipment

Maintaining geomembrane welding equipment is crucial for optimal performance. Regular inspections can prevent major issues. Always check for wear and tear on components. This ensures the machine operates smoothly and efficiently. It’s essential to keep the welding tips clean. A small buildup can lead to poor weld quality.

Proper storage of the equipment is also important. When not in use, keep machines in a dry place. Avoid exposure to extreme temperatures or moisture. These factors can deteriorate the materials over time. Regularly update the maintenance logs. This reflection can help track performance and identify patterns.

Don’t overlook minor repairs. Addressing small issues early can prevent larger breakdowns. It's common to get busy and forget these tasks. A short daily checklist could be beneficial. This practice will ensure that equipment stays in top shape, ready for any project.